There are a number of factors that cause the structure to excessively lean or settle. For example, liquefaction of soil beneath the foundation after earthquake occurrence, excavation, groundwater condition variation, poor soil bearing capacity, inappropriate foundation and construction defects.

When a building over leaned or settled, then it is necessary to uplift it properly to regain required safety and prevent undesired consequences. Building rectification techniques are used to uplift such structures. These methods will be discussed in the following sections.

Fig.1: Over Tilting of Several Buildings and Towers in the World

Methods to Rectify Over Leaned Buildings and Structures

Rectification methods used to uplift over tilted buildings include:

- Compaction grouting method

- Chemical grouting method

- Underpinning method

- Micro-Tunneling method

1. Compaction Grouting Method

It is one of the methods used to rectify buildings that tilted or settled excessively.

Compaction grouting technique needs detailed preparation and plan prior to the beginning of the work.

For example, it is required to determine grouting pressure, grouting depth, grouting rate, configurations of grouting stations, and the method used to execute the task.

It is necessary to equip the structure with adequate number of monitoring devices. This is to observe the process and makes suitable changes during lifting operation if it is needed.

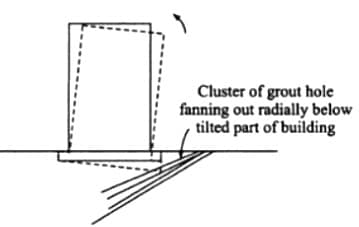

There are two methods used for compaction grouting including drilling holes through floor slab of the building vertically and perform the work or dug holes at a specified degree from the side of the structure.

Fig.2: Rectification of Tilted Building

It should be known that the function of the structure may be disrupted or stopped when compaction grouting is conducted through holes dug through the floor, but its effect is great. However, the latter technique will not influence building functionality, but it is less effective compared with former technique.

It is recommended to concentrate grouting stations on the largest settled locations and major grouting points should be arranged at the greatest depth.

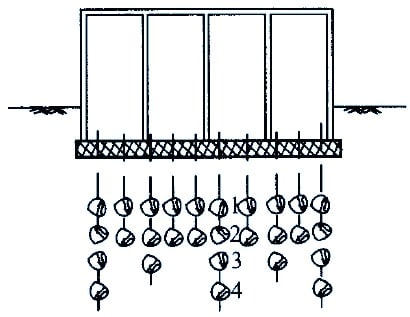

Fig.3: Grouting positions of compaction grouting technique, numbers show the sequence of grouting

Regarding minor grouting points, they are aimed at smaller settled locations and their depth is smaller.

Finally, the process of grouting is begun from the major points configured at largest settled area and then minor points close to the major stations. If the settlement is large, then the process may be conducted in more than one stage.

2. Chemical Grouting Method

Chemical grouting is another technique used to restore tilted building to its original position. This method is economical but grouting process requires substantial care to achieve the desired outcome.

If chemical grouting is not carried out properly, unanticipated grout flow may occur and may lead to pipe and structural damages and decline grouting effect.

Similar to compaction grouting, it is necessary to establish detailed plan grouting pressure, injection point configuration, techniques to prevent the disappearance of grouting flow before the grouting process is started.

The determination of injection point arrangement, amount of injected grouting, and grouting pressure is based on the experience and observation obtained from devices placed on the structure.

Regarding methods used for prevention of grout fugacious flowing, either sheet piles placed within grouting range or grouting setting time reduction is employed.

Fig.4: Chemical Grouting

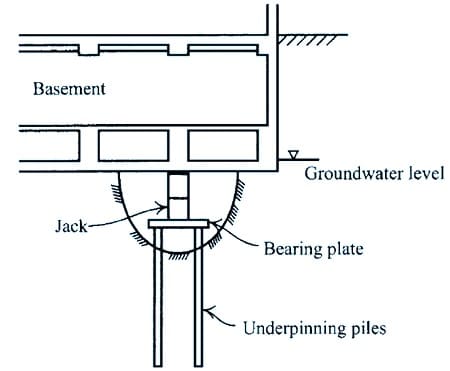

3. Underpinning Method

Underpinning technique used to restore verticality of tilted structures. It is more expensive compare with other aforementioned methods. Moreover, this technique can be used to rectify structures that constructed on individual footing and mat foundation.

Furthermore, underpinning method lacks those disadvantages that encountered when compaction grouting or chemical grouting is employed. For example, grout flowing to location which is not planned and predicted, and improper uplifting or columns which is possible in the case of chemical and compaction grouting.

Underpinning method procedure involves excavate working place, for underpinning pile construction, around the foundation and then set jacks between the foundation and pile cap to uplift the structure, and lastly carry out load transfer operation.

As far as disadvantages of underpinning are concerned, poor design of underpinning may lead to increase the settlement of the structure.

Fig.5: Using underpinning method to restore building tilt

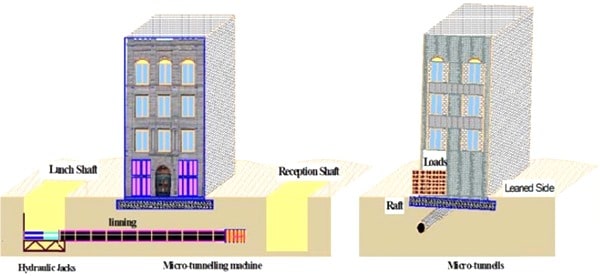

4. Micro-Tunneling Method

This method is used for structures which is built on cohesive soil and suffered from limited leaning. In this case, it might be more feasible to create deformations under less settled side of the structure using micro tunnels.

The procedure includes application of micro tunneling for drilling unsupported small holes under less settled side of the structure, then these holes would be deformed due to load of the structure and additional loads imposed to deform small holes.

When these holes are collapsed under structural load and additional load, a sliding surface would be produced, and the foundation would rotate opposite the direction of inclination.

Fig.6: Micro tunneling method used to restore tilt building to its original location