Barbed wire is a type of fencing wire constructed with sharp edges or points arranged at intervals along the strand(s). It is used to construct inexpensive fences and also on walls surrounding secured property. Barbed wire was the first wire technology capable of restraining cattle.

Barbed wire fencing requires only fence posts, wire and fixing devices such as staples. It is simple to construct and quick to erect by even an unskilled fencer. The wire is aligned under tension between heavy, braced, fence posts (strainer posts) and then held at the correct height by being attached to wooden posts and battens, or steel star posts.

To prevent humans crossing through or over barbed wire fences, many prisons and other high-security installations construct fences with razor wire, a variant which instead of occasional barbs features near-continuous cutting surfaces sufficient to injure unprotected persons who climb on or over it.

More popularly known as B.R.C, is a welded steel wire mesh manufactured from bright drawn wire, electrically welded at the intersections. Since weld mesh is welded at intersections it can be cut to shapes required by users and does not need a frame to hold it.

Due to its properties B.R.C has an infinite number of uses and is also suitable for general wire works

Extensively used for all forms of fencing

Agricultural and horticultural applications

Used for decorative, packaging and material handling purposes

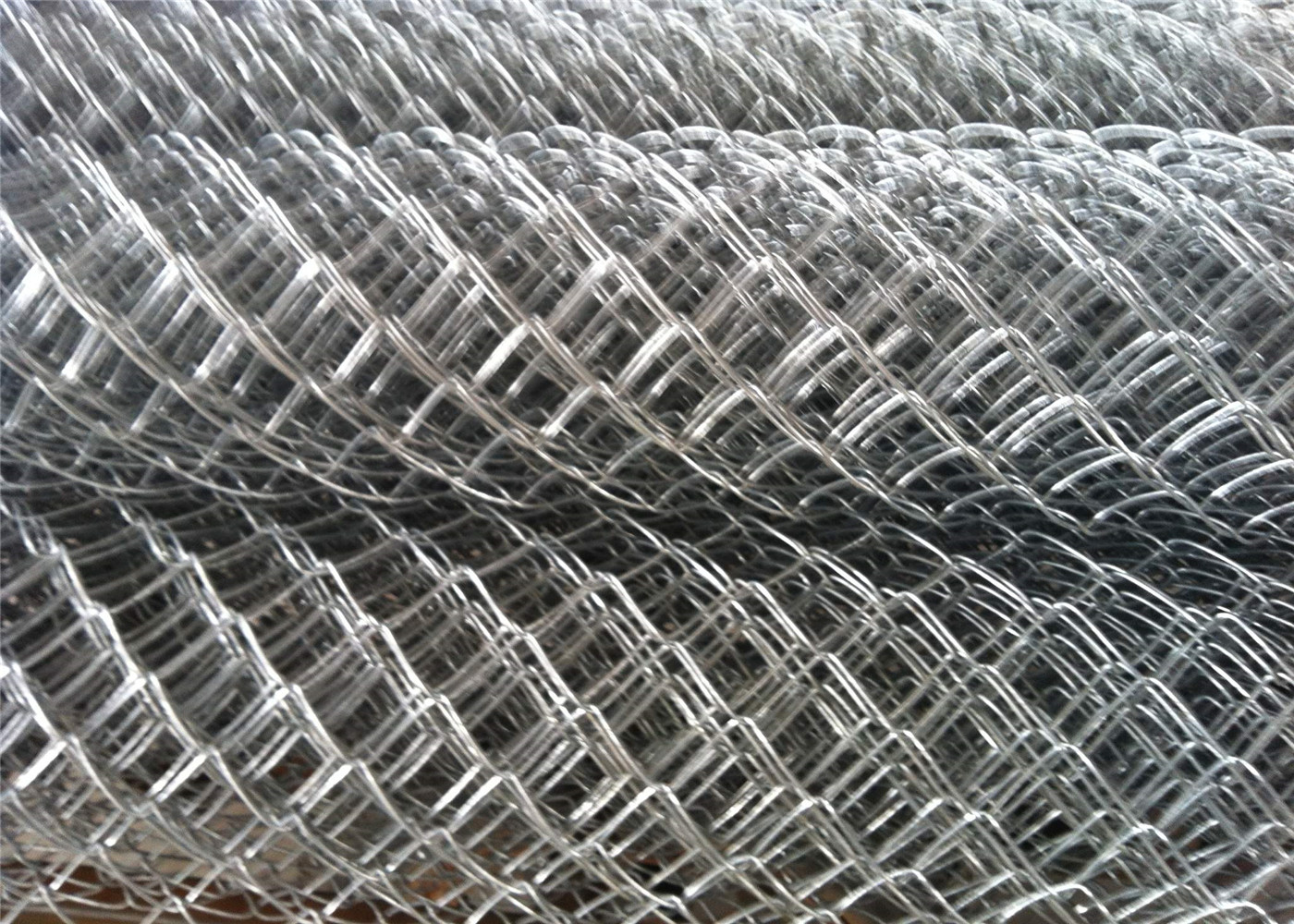

A chain link fence is a type of woven fence usually made from galva-nized wire. The wires run vertically and are bent into a zigzag pattern so that each ‘zig’ hooks with the wire immediately on one side and each ‘zag’ with the wire immediately on the other. This forms the characteristic diamonda pattern seen in this type of fence.

The popularity of chain link fence is due to its relatively low cost and eases of installation. A further advantage is that due to the open weave, chain link fences are transparent, and do not obscure sunlight from either side of the fence.

Gabions are rectangular cages made of hexagonal double-twist wire mesh filled with appropriately sized rock or quarry stone.

Gabions are rectangular cages made of hexagonal double-twist wire mesh filled with appropriately sized rock or quarry stone.

The gabions are sub-divided into cells by inserting diaphragms which are mesh panels with the same characteristics as the external sides, spaced 1m from each other to give the structure strength and facilitate its speedy construction. The galvanized wire, before being woven, can be coated with special PVC

(polyvinyl chloride) coating 0.5mm thick. This additional coating gives full protection from corrosion in marine or heavily polluted environments. Gabions are used in many situations including the stabilization of earth movement and erosion, river control, reservoirs, canal refurbishment, landscaping and retaining walls. They can be manufactured in welded mesh or woven wire.

Gabions are compartmentalized rectangular containers of galvanized steel hexagonal wire mesh that are filled with stone. While maintaining sufficient strength to contain the stone used as a fill, gabions must be able to settle, twist, and conform to channel and foundation shifts. In order to meet the various needs, gabions must have the following features:

- Hexagonal mesh pattern critical points

- Double twist to avoid unraveling

- Reinforcing wires woven into corners to reinforce critical points

- A diaphragm securely attached at the base that will prevent the shifting of some and reinforce the gabio.

It is used to construct inexpensive fences and also on walls surrounding secured property.